Explore Our Service

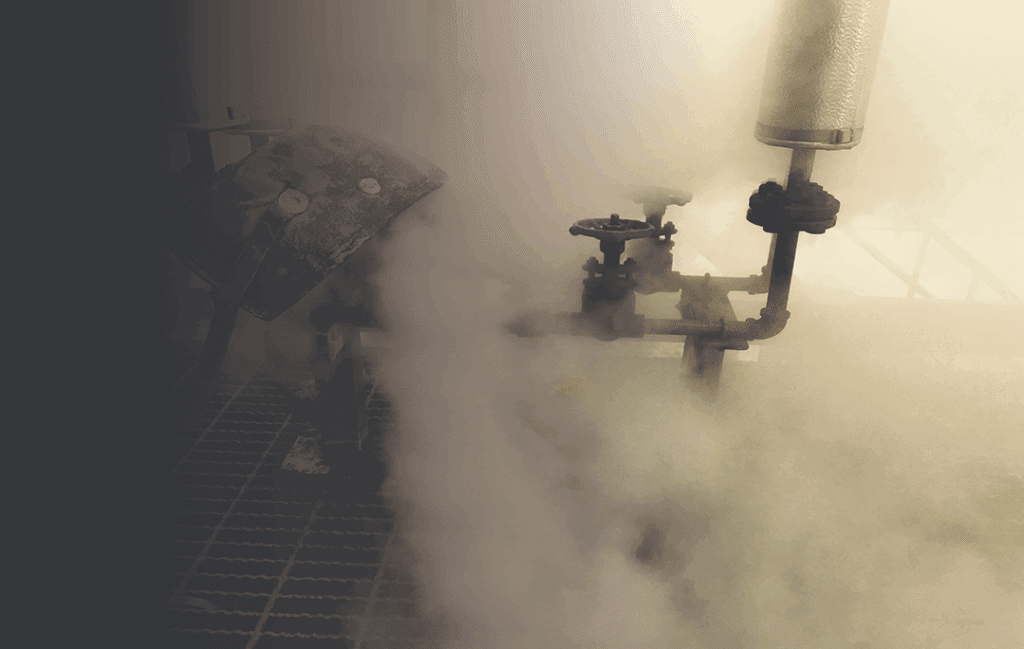

Poor steam management can lead to lost production time and less product out the door. Coyle Steam Management (CSM) helps you get more out of your steam system. We work with facilities to improve efficiency and keep systems running smoothly, reducing maintenance costs in the long run.

Our team looks at your entire steam system with tools like ultrasonic listening devices, temperature readers, and flow measurement equipment. We gather real data and share it with you to guide next steps.

From there, we identify problems or areas for improvement and offer reliable product options from trusted manufacturers. These updates lead to real results: lower energy use, better condensate recovery, longer equipment life, and long-term cost savings.

Coyle Supply works with your team to prioritize improvements and share the best product offerings for your application. We partner with reputable brands to offer reliable components and use our expertise to help you choose the right products for your needs.

Coyle Supply is your go-to source for steam management solutions. We combine an extensive product inventory with specialized knowledge to solve challenges other suppliers can’t address. Our comprehensive approach means you get everything you need from a single partner who understands your operations inside and out.

One Partner

Source everything you need for steam (and beyond) through our trusted network.

Decades of Experience

We’ve spent years partnering with plants like yours, so we know what works and why it matters.

Real Results

We deliver data-backed insights, helping you make smart, cost-saving decisions for your facility.

Innovative Problem-solvers

Challenging applications don't scare us. We work closely with manufacturers and engineers to find creative solutions that actually work.

Our team uses a combination of ultrasonic listening devices, temperature reading devices, best practice piping knowledge, and visual inspection to help our customers’ steam systems run efficiently and safely.

Not necessarily! Our team is happy to make a site visit and help you diagnose some steam issues at no charge. Coyle Steam Management charges for steam trap testing, full system analysis, and official reporting, but we are happy to share our knowledge with you.

Using industry-leading steam trap testing tools, we check your system for leaks and inefficiencies. After the test, you'll receive an in-depth report detailing your system's pass/fail status, failure types, and estimated cost savings.

Failed steam traps cause energy loss and increased fuel consumption, raising your system's operating cost. Additionally, improper condensate removal can damage your equipment.

Yes. Identifying failed or inefficient steam traps helps reduce energy waste and lower your system's operation and maintenance costs over time.

Poor steam quality risks a plant's production and safety. It can reduce heat transfer efficiency, damage equipment, and cause costly downtime. In some cases, it creates safety hazards like water hammer, which puts personnel and equipment at risk.

Our team is ready to deliver quality flow components and expert services. Get in touch with us today.

EMAIL ADDRESS

[email protected]